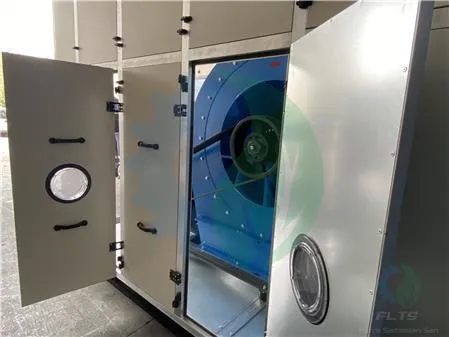

Jet pulse cartridge filter is used extensively for cleaning industrial process gases. These filters come to meydana from filter bags, compressed air system, air lock, conveyor unit, automatic control system and fan selected in accordance with the optimum number and dust quality in the steel structure.

Jet Pulse cartridge Filter is the solution to the Decontamination problems and is in the first place among the most used filter types today.

In Jet Pulse Filters, the principle is that the dusty gas is cleaned from the dust by passing through the outside of the base bag and at the same time, the combined dust is collected on the outer surface of the bag by dropping it in the golden bunker with compressed air.

In the bunker, the total dusts, dust discharge elements can be taken with the filter filter The dusts can be produced again by transporting the system through the bare elements

Cartridge filters are one of the dust collection systems that have overcome the challenges of the very industrial dust type and are used in more detail.

It is used to maintain air quality in the working environment. The Cartridge Filter is suitable for air with lighter to heavier particle volumes. It reduces air pollution in its business and provides a healthy working environment for employees. Cartridge Filters are used as feed in Construction, Mining, pharmaceutical, Food and beverage, Biotechnology, Manufacturing and many more industries.

Cartridge type dust collection system, also known as Cartridge Filter, is used as a broadcast in industries where air pollution is high. The production times of various industries lead to a pollutousenvironment. The cartridge filter ensures the effective removal of damaged batches from the air and a healthy working environment. These high-tech machines offer high performance with the lowest downtime. They can also be constantly worked at production facilities of various industries. Jet pulse cartridge filters not only reduce the risks of down-air pollution in the environment, but also minimize the downtime of equipment in your production facility.

Dust collection systems automotive, food, pharmaceutical, plastics, packaging, metalworking, ceramics, plants, rubber production, Paper Manufacturing, all industrial facilities engaged in the production of cement and iron and steel process center or a local unit of harmful dust collecting process.

Jet pulse cartridge filter is used in central system dust and smoke extraction applications. The bulk polluted air is brought from the source to the filter with air channels designed in appropriate diameters and thicknesses according to the type of dust.

Folds that fall at the dirty air filter inlet coming into the dust collection system or cyclone filter installation will be made in front of the dirty air inlet of the dust collection site, preventing large and degrading parts from hitting the bags directly, thus prolonging the life of the filters.

The retained powders are cleaned automatically in the number of explosive cleaning system. The total bucket or air lock at the bottom of the bunker is used as directed dust waste or recycling. The cleaned air is the desired average to suck from the cabin by means of a fan.

The biggest purpose of dust collection systems is to provide a healthier environment for the polluted air, cleanliness and work in working environments.

Dust collection systems, which have high suction in the working environment, attract all harmful substances into themselves in this feature and make the environment healthier.

If a suitable dust collection and filtration system is not used, ise leads to safety deterioration in its products and breakage in production facilities. The most important, dust and especially Decodable particles can create occupational health and safety problems that cannot be ignored, causing hidden diseases in employees.

Dust collection systems are an important place to create an optimal working environment and to prevent the phenomena of dust-related machine equipment.

It is a very important equipment for the performances given in a very industrial facility. Performance management is all about profit, as it effectively minimizes machine downtime and is the right fit for a healthy workplace environment. Considering all these issues, making the right choice is very important when choosing a dust collector.

As a result of extensive industry experience, a tremendous expertise in manufacturing high-quality dust collection systems according to customer requirements has been developed. Our dust collectors, which are synonymous with superior quality and unsurpassed performance, are one of the most preferred of their companies. We not only offer a product, but also believe in producing a solution according to the needs of our customers. Our customer-oriented approach in dust collection system production has helped us to win as a reliable dust collection system production in Turkey.

Treme dust collection system

The Capped Dust Collection System is used for collecting medium release dust in the product discharge area. It is designed to be obtained in the highest efficiency according to the type of powder.

The Prince of Work:

Products such as grain, stone mine, wood powder poured into the product intake pit pass through the treme screen and special dust-free lids in turn and reach the treme in a short time. The powders formed at this time are shown upward movement training. In the specially designed treme bottom system, only the hatches with product flow are opened and the product flow does not go up from this part.

The dust collection system provides collection by pulling the dust to the filter panels in the suction system.

the use of the jet - pulse technique is ensured by the use of combined powders as means. Thanks to the spiral located under the panel, total dust is removed from the system.

The total powders are given to the tremor again from the exit of the airlock as an option or subjected to the bagging process.

Cartridge filter

jet pulse filter

Jet pulse cartridge filter

jet-pulse-cartridge Ex-proof (Atex) dust collection system