Working Principle of Jet Pulse Filter

Jet pulse bag filter ranks first among the most preferred filter types today with the solutions it brings to the Decontamination problems.

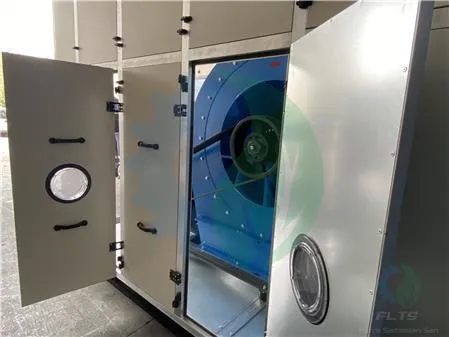

The principle of Jet Pulse Filters is that the dusty gas is dusted by passing it from the outside of the felt-based bag into it, and at the same time, the dust accumulated on the outer surface of the bag is collected by dropping it into the bunker under the body with compressed air.

The dust collected in the bunker is taken out of the filter by means of the dust discharge elements, the usable dust is transported to the system by means of the transport elements and included in the production again.

Dust collection systems are the process of collecting harmful dust coming out of the process centrally or locally in a unit in all industrial facilities engaged in food, pharmaceutical, plastic, packaging, metal processing, ceramic plants, tire production, paper manufacturing, cement and iron and steel production.

Compared with other dust collectors, the bag filter has the advantage of higher filtration efficiency, which is generally over 99.99%. Therefore, the gas discharged from the dust collector contains less dust and can meet the requirements of environmental protection emission standards;

Bag filters are manufactured for use in enterprises where the dust density is high. Devices The filter is selected depending on the structure of the dust, its type, grain size, mass weight and density of the dust and is produced to reduce the dust in the environment to a minimum level.

Jet pulse bag filter is generally used in central system dust and smoke extraction applications. The dirty air collected from the source is brought to the filter by air channels designed in appropriate diameters and thicknesses according to the type of dust.

Sparks, large and abrasive parts that may come by reducing the suction speeds at the dirty air filter inlet coming into the dust collection system or installing a cyclone filter in front of the dirty air inlet of the dust collection system are prevented from hitting the bags directly, thus prolonging the life of the filters.

The retained dusts are cleaned automatically thanks to the explosive cleaning system. The dust directed to the collection bucket or airlock at the bottom of the bunker is provided to be used as waste or recycling. The cleaned air is sucked from the cabin by means of a fan and pressed to the desired environment.

The main purpose of dust collection systems is to clean the polluted air in the working environment and to provide a healthier environment to the employees.

Dust collection systems, which have a high suction power in the working environment, attract all substances that are harmful to health into themselves thanks to this feature and make the environment healthier.

Industrial Type Explosive (Jet Pulse) Bag Filters

If a suitable dust collection and filtration system is not used, it leads to deterioration of the purity of the products and contamination in the production facilities. Most importantly, dust and especially breathable particles can create occupational health and safety problems that cannot be ignored because they cause serious illnesses in employees Dec.

Dust collection systems take an important place in creating an optimal working environment and in order to prevent the disadvantages of machine failures due to dust.

It is a very important equipment for efficient performance in most industrial plants. Performance efficiency is directly related to profit, as it effectively minimizes machine downtime and maintains a healthy workplace environment. Considering all these issues, it is very important to make the right choice when choosing a dust collector.

Bag filter performs its function as 99.9% by removing dust from the source in enterprises with high dust density. Filter bags and filter wire cages, which are side equipment in bagged filter, are also of great importance. The compatibility of wire cages with filter bags, dust permeability and static calculations are among the most important equipment of dust collection systems.

In order for a dust collection system to work effectively, all components that make up the system must be selected and designed correctly.

Iron and steel industry filter system

As a result of extensive industry experience, we have developed tremendous expertise in manufacturing high-quality dust collection systems according to customer requirements. Our dust collectors, which are synonymous with superior quality and unsurpassed performance, are one of the most preferred options of companies. We not only offer a product, but also believe in producing a solution according to the needs of our customers. Our customer-oriented approach to dust collection system production has helped us to gain a reputation as a reliable dust collection system manufacturer in Turkey.

THE IMPORTANCE OF DUST COLLECTORS

THEY IMPROVE HEALTH AND SAFETY

When the air is filled with dirt, dust, debris, chemicals or gases, it can affect the lungs of anyone who breathes this air. Not only that, but also this particle

it may accumulate on or near the equipment, posing a significant fire hazard. With a dust collector, these pollutants are removed from the air, the air is cleaned and the safety of everyone inside is improved.

THEY INCREASE EFFICIENCY

When dirt, dust and residue accumulate on the equipment, it can get inside by interfering with the mechanics of the equipment. This leads to slower machines and malfunctioning equipment.

may be. Machines that have been compromised require constant attention and repair. Dust collectors eliminate this risk and ensure that your machines operate at optimal performance.

THEY LEAD TO BETTER PRODUCT QUALITY

With the dust in the air, it can accumulate on the products during the production process. This can negatively affect the quality of the finished product. Dust collectors are in the air

by significantly reducing dust, fumes and fumes, keeping them away from finished products, it improves their quality and customer satisfaction.

THEY WILL HELP YOU MEET THE COMPLIANCE REGULATIONS

There are numerous laws and regulations in force for workplace safety. Some of these regulations are related to the environment and the quality of the air. Poor air quality can cost you a lot of money, not only in the form of fines, but also by creating potential hazards that can damage your factory or affect your employees. In addition to keeping everyone (and everything) inside the building safe, factory dust collectors also help you comply with government regulations.

THEY HELP TO ENSURE HAPPIER EMPLOYEES

Employees suffer when the air quality is poor. As a result, they become unhappy and start looking for work elsewhere. Dissatisfied employees

it does not work well, and a high employee turnover rate can be costly. Keeping the air clean and healthy with a factory dust collector allows you to keep wonderful and happy people at work, Jul ing the morale of your employees.

When the air is filled with dirt, dust, debris, chemicals or gases, it can affect the lungs of anyone who breathes this air. Not only that, but also this particle can accumulate on or near the equipment, posing a significant fire hazard. With a dust collector, these pollutants are removed from the air, the air is cleaned and the safety of everyone inside is improved.

Electrostatic powder coating filtration system

Treme dust collection system

Dust Collection System with Lid; It is used to collect dust emitted to the environment during product unloading. It is designed in such a way that the highest efficiency is obtained according to the type of powder.

Working Principle:

Grain products poured into the product intake pit, in turn, pass through the treme grate and special dust-proof lids and reach the treme interior. The dust formed at this time tends to move upwards. In the specially designed under treme system, only the lids with product flow are opened and the dust cannot go up because there is product flow from this part. At the moment when the product flow is interrupted, the lid will close under the influence of gravity.

Thanks to the aspiration fans, dust is attracted to the filter panels and collection is provided.

Dust accumulates in the filters located in the upper part. using the jet – pulse technique, the accumulated dust is discharged instantly. Thanks to the spiral located under the panel, the collected dust is removed from the system.

The collected dusts are optionally fed back to the tremor from the exit of the airlock or subjected to the bagging process.

Advantages:

• Easy Installation

• Long Lasting Design

• High dust holding capacity

* Increased product quality and the possibility of longer storage

Foundry ventilation and dust collection systems

At the stage of establishment of foundries or improvement of an existing dust collection system, the expert engineer and technician staff is one of the rare companies in the sector that can perform the Project Design, Manufacturing and Project Implementation stages alone.

In which processes of foundries does a dust collection system need?

Aluminum melting January filtration system

DUST AND SMOKE COLLECTION FROM January SMELTING FURNACES

Dust and smoke filtration system in induction January, bulk and cooling lines is very important in terms of the following;

Productivity

Occupational health and safety

Indoor air quality – Legal regulations

Sustainability

Environment

In order to offer the best solution for the filtration of the melting section, we work closely with January manufacturers. Dust January January and smoke extraction from induction hobs can be provided with hydraulic hoods produced by manufacturers of January, as well as from the canopy or according to the charging method can be provided with horizontal hoods mounted next to the stove. The smoke released during the ductile iron process can be collected with movable hoods and cleaned in the filter unit

Collecting dust

Jet pulse filter

Jet pulse bag filter

Jet pulse cartridge filter

Ex-proof Atex dust collection system

Jet pulse ex-proof atex dust collection system

MODULAR FILTER