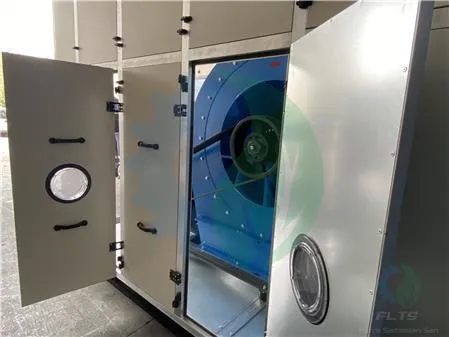

It is important to note that the sizes of cyclones can vary greatly. The size of the cyclone largely depends on how much flue gas needs to be filtered, so larger operations tend to need larger cyclones.

How does it work

Cyclone separators work like centrifuges , but with a constant supply of polluted air. In a cyclone separator, dirty flue gas is fed into a chamber. The inside of the compartment forms a spiral vortex, similar to a tornado. This spiral formation and separation, the lighter components of this gas have less inertia, so it is easier for them to be affected by the vortex and move upwards. On the contrary, the larger components of the particulate matter have more inertia and are not easily affected by the vortex.

Cyclones, which are included in the category of industrial dust collectors, are equipment used directly or before jet filters for collecting solid particles. Cyclones work according to the principle of separation from dust after a cyclonic movement that takes place at the entry point of the dust vehicle. The airlock and the weighted hatch can be counted as the equipment of the unit. The cyclone collects coarse-grained material according to its structure, because fine materials in the dusty air can be removed outside. If this value is within the accepted limits, the cyclone itself can be used as a dust collector.

Cyclones can be produced in different designs according to the characteristics and efficiency of the powders. Cyclones can be produced as horizontal and vertical Cyclones. Under current conditions, vertical cyclones are usually used. The criterion that determines the cyclone size is the absorbed air flow rate. Cyclones that are not selected or produced in the appropriate sizes become problems themselves instead of producing solutions. Therefore, as a result of the correct operation, they must be used in the processes.

Since these larger particles have difficulty following the high-speed spiral motion of the gas and the vortex, the particles hit the inner walls of the container and fall into a collection chamber. These compartments are shaped like an upside-down cone to support the collection of these particles at the bottom of the container. The cleaned flue gas comes out from the top of the chamber.

Most cyclones are made to control and remove particulate matter that is larger than 10 micrometers in diameter. However, highly efficient cyclones are available that are designed to act on particles as small as 2.5 micrometers. Also, these separators are not effective on excessively large particulate matter. For particles with a size of about 200 micrometers, gravity settling chambers or momentum separators are a better option.

Among all the particle control devices, cyclone Decouplers are the cheapest. They are usually used as pretreatment before the flue gas enters more effective pollution control devices. For this reason, cyclone separators can be seen as “coarse separators” before the flue gas reaches the fine filtration stages.

Cyclone Decouplers can usually remove anywhere between 50-99% of all particulate matter in the flue gas. How well cyclone separators are actually able to remove this substance depends largely on the particle size. If there is a large amount of lighter particulate matter, less of these particles can be separated. Therefore, cyclone separators work best on flue gases containing large amounts of large particulate matter.

There are many advantages and disadvantages to using cyclone separators. Firstly, cyclone separators are useful because they are not expensive to install or maintain and have no moving parts. This keeps maintenance and operating costs low. Secondly, the extracted particulate matter is collected while it is drying, which facilitates its disposal. Finally, these units take up very little space. Although effective, there are also disadvantages to using cyclone separators. The main reason for this is that standard models cannot effectively collect particulate matter smaller than 10 micrometers, and machines cannot handle sticky or sticky materials well.