water filter systems The water in the lower water chamber of the bunker, together with the operation of the suction fan, creates a water turbulence in the specially designed (with stainless separator) washer cell in the system. The dirty air / particles desired to be filtered are passed through this water turbulence, and washing takes place and the particles in the dirty air are precipitated in the lower bunker water tank of the machine. Wet Filter is a system specially designed for applications where dry type filtration methods are insufficient or risky. It offers permanent solutions for the precipitation of the particles in the polluted air that are formed during the metallized coating processes and that have solvent or oil-based flammable and combustible properties (paint). The Water Filter is a very different and much more effective system than conventional sprinkler or sprinkler washing systems. In conventional water washing systems, there is an external circulation pump, external water tank, settling pool or equipment that requires maintenance. There are no such equipments found in conventional water washing systems in the Water Filter that we manufacture. The system is guaranteed to operate more efficiently and with minimum downtime, since these equipment, where the most malfunctions occur in water-washed systems, are not found in the specially designed Water Filters that we manufacture. All of our specially designed Water Filter applications have replaced the tried and unsuccessful applications of classical water washing systems. The control panel is specially designed by our automation team so that the Wet Filters we manufacture can work synchronously with the machine or station to which they will serve. Remote start/stop, operation, status signals and alarm signals of the Water Filters, the control panel prepared by our automation team, can be given to the enterprise as a dry contact, allowing remote machine control and traceability. Specially designed Aqueous Filters generally give successful results in Metallized Coating, Wire / Metal Band bending and forming stations, Wet painting lines, Glazing and polishing stations, Filtering of oily or moist / vaporous gases formed during the manufacturing phase.

Aqueous Filter

Water filter systems

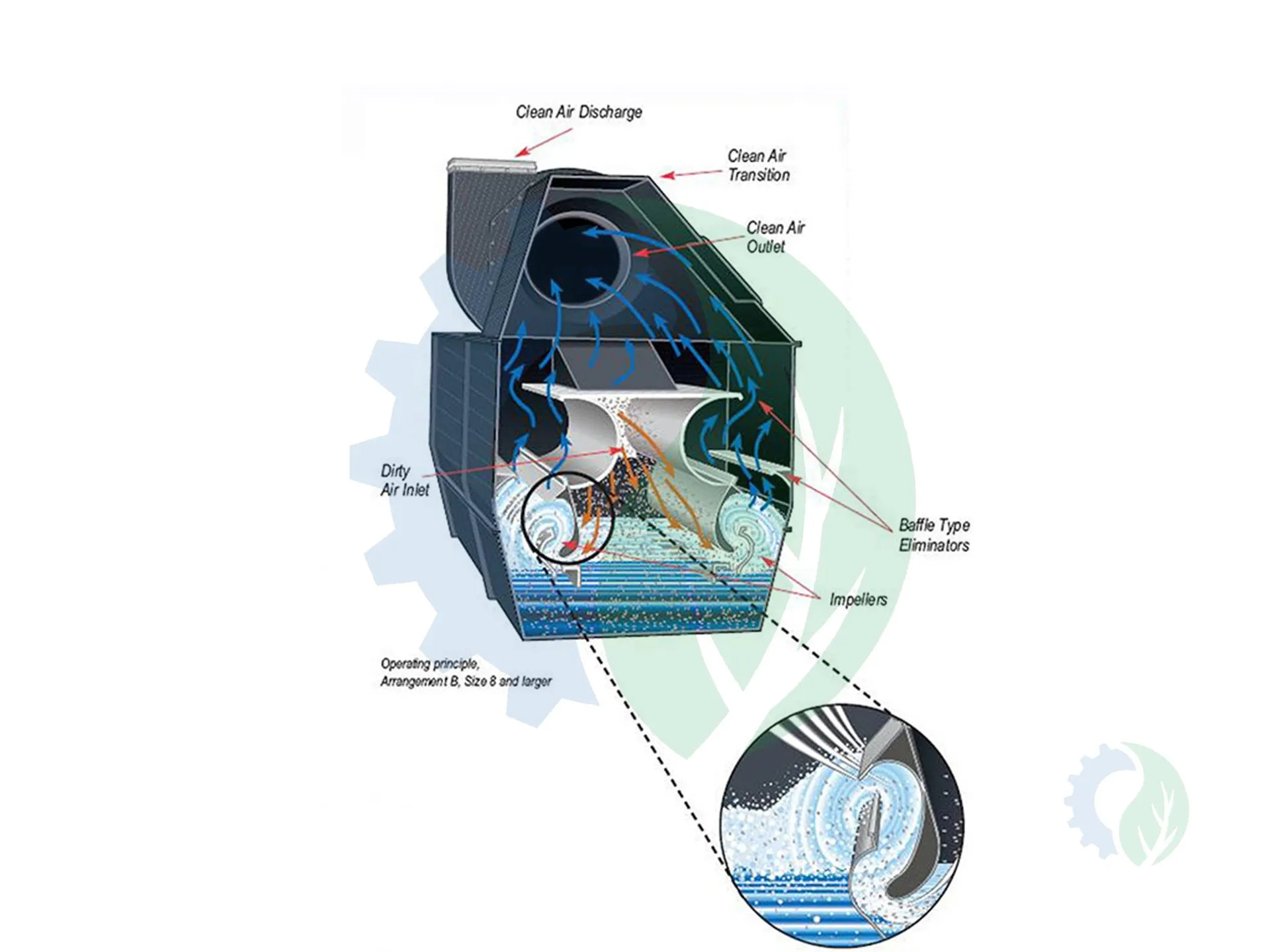

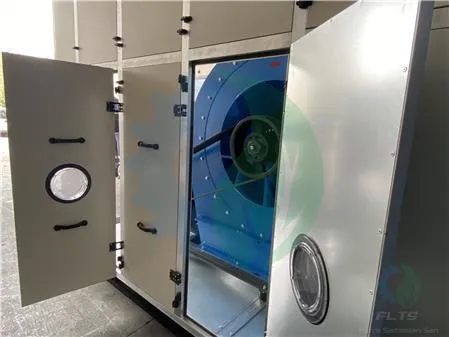

The water in the lower water chamber of the bunker, together with the operation of the suction fan, creates a water turbulence in the specially designed (with stainless separator) washer cell in the system. The dirty air / particles desired to be filtered are passed through this water turbulence, and washing takes place and the particles in the dirty air are precipitated in the lower bunker water tank of the machine.

Wet Filter is a system specially designed for applications where dry type filtration methods are insufficient or risky. It offers permanent solutions for the precipitation of the particles in the polluted air that are formed during the metallized coating processes and that have solvent or oil-based flammable and combustible properties (paint).

The Water Filter is a very different and much more effective system than conventional sprinkler or sprinkler washing systems. In conventional water washing systems, there is an external circulation pump, external water tank, settling pool or equipment that requires maintenance. There are no such equipments found in conventional water washing systems in the Water Filter that we manufacture. The system is guaranteed to operate more efficiently and with minimum downtime, since these equipment, where the most malfunctions occur in water-washed systems, are not found in the specially designed Water Filters that we manufacture.

All of our specially designed Water Filter applications have replaced the tried and unsuccessful applications of classical water washing systems.

The control panel is specially designed by our automation team so that the Wet Filters we manufacture can work synchronously with the machine or station to which they will serve. Remote start/stop, operation, status signals and alarm signals of the Water Filters, the control panel prepared by our automation team, can be given to the enterprise as a dry contact, allowing remote machine control and traceability.

Specially designed Aqueous Filters generally give successful results in Metallized Coating, Wire / Metal Band bending and forming stations, Wet painting lines, Glazing and polishing stations, Filtering of oily or moist / vaporous gases formed during the manufacturing phase.