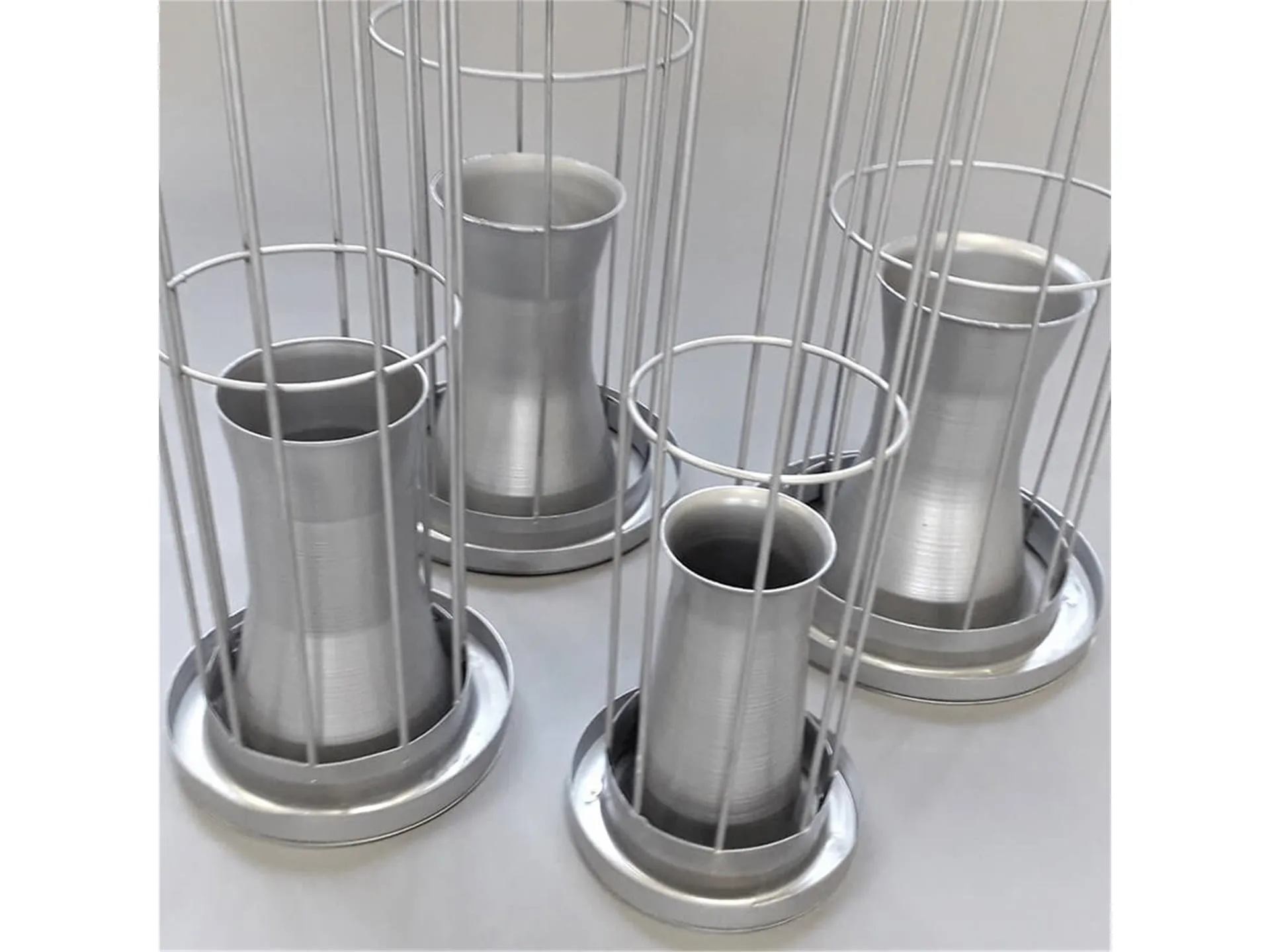

Filter Cages

When producing the filter cages, the iron bars, which are in rolls, are first made flat. Then these straight bars are cut according to the requested cage length of our customers. The cut bars are welded by putting them on an automatic punting machine and with iron rings at certain distances. After the filter cage takes the desired shape according to the requested diameter and length, the lid is installed on the lower part and the venturi is installed on the upper part. The filter cage, which has received its final form, is sent for delivery after being painted with galvanized coating or electrostatic paints.

We manufacture all filter wire meshes of all sizes and diameters in one piece or multi-piece. In addition to this, we also manufacture cages according to venturi type as aluminum venturi, conical sheet venturi, pipe type venturi.

We also have special productions for flat, horizontal, asphalt plants and with star rings. For these special productions, you can get the most suitable price offer in the market conditions by contacting us.

Thanks to the stainless wire, we also manufacture filter bags for filter wire cages that you will use for a long time. Polyester, antistatic, cotton, Nomex Meta-Aramid, PTFE, polypropylene, monofilament, glass fiber, P-84 etc. our products are guaranteed as Filter systems, which is the company you can trust in filter production with our wide range of materials.

We would be glad to be by your side in case of any requests and problems regarding jet pulse filter systems.